venice

venice

400-8866-090

test philosophy:

The principle of supercritical fluid extraction separation process is that supercritical fluid has a special dissolution effect on fatty acids, alkaloids, ethers, ketones, glycerides, etc. The relationship between the dissolution capacity of supercritical fluid and its density is used, that is, the influence of pressure and temperature on the dissolution capacity of supercritical fluid is carried out. In the supercritical state, the supercritical fluid is contacted with the substance to be separated, so that it selectively extracts the components of polarity, boiling point and molecular weight in turn. Of course, the extracted material corresponding to each pressure range cannot be a single, but the optimal proportion of mixed components can be obtained by controlling the conditions, and then the supercritical fluid becomes an ordinary gas by means of pressure reduction and temperature rise, and the extracted material is completely or basically precipitated, so as to achieve the purpose of separation and purification. Therefore, the supercritical fluid extraction process is a combination of extraction and separation。

technical specification:

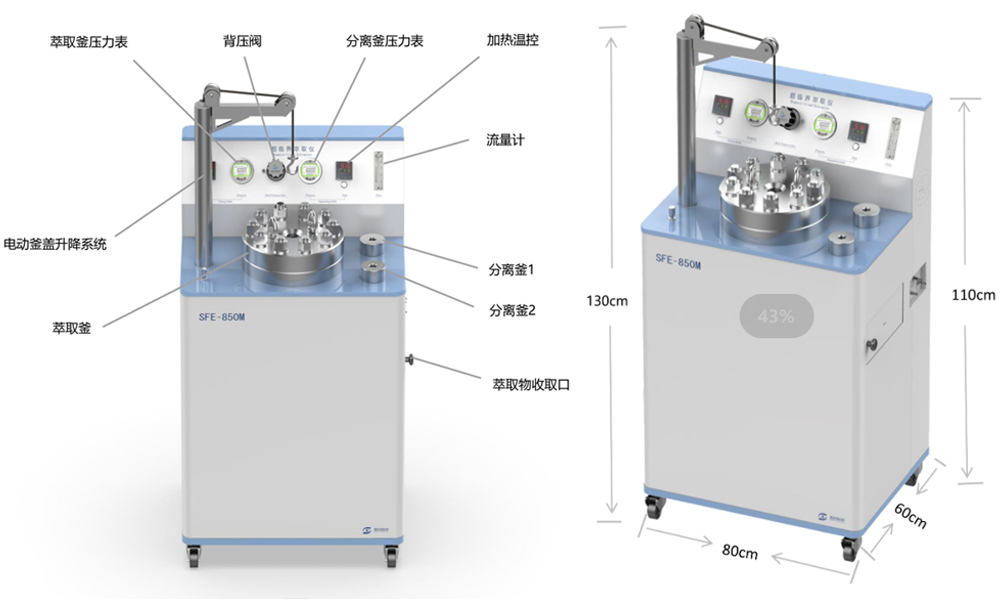

1、extraction kettle :Volume 3L-30l, 316 stainless steel integrated processing, equipped with electric heating system, temperature adjustable, equipped with special cylinder, the maximum working pressure of 50MPa, can be added to the number of extraction kettle;

2、Separating still:Volume 500-3000ml, 316 stainless steel integrated processing, equipped with electric heating system, temperature adjustable. The maximum working pressure is 20MPa, and the number of separation reactors can be increased;

3、Separator window:The separation kettle has a sapphire window to observe the progress of extraction collection;

4、CO2high-pressure pump:flow velocity:0-100ml/min,Maximum working pressure 50MPa, with front cooling tank, with sapphire viewing window and co2 recovery inlet. Constant current constant pressure mode is optional, with software can automatically control the flow rate and pressure。

5、Entrainment pump:Flow rate 10ml/min, maximum working pressure 40MPa, optional;

6、Gas path control system:Globe valve + trimmer valve + back pressure valve Gas path control system, can accurately adjust the pressure and gas flow rate;

7、fail-safe systemEquipped with automatic pressure relief system, overpressure automatic pressure relief to ensure that the pressure is in a controllable range;

8、heating system:Electric heating temperature control, control range of room temperature -200℃, temperature control accuracy ±1℃;’

9、Pressure indicators:Each autoclave is equipped with an independent digital pressure gauge for easy control and observation of pressure changes in the autoclave;

10、Carbon dioxide recovery system:Carbon dioxide recovery pump + two-stage gas purification device, can be carbon dioxide recycling, optional;

11、electric lifting:Integrated electric kettle cover lifting system, easy to operate, save manpower;

12、appearance:Integrated design, compact structure, high degree of automation, simple operation, high cost performance, suitable for pilot users。

Superior Characteristic:

1、Integrated design, small footprint, save laboratory space;

2、The overall design is simple and practical, greatly reducing the required operation and greatly reducing the difficulty of operation;

3、More precise and refined valves and pipelines are used to improve the accuracy of pressure and flow under the premise of ensuring pressure resistance;

4、The precise design of pipeline, the reduction of extraction residue and the increase of extraction rate are of great significance for research samples;

5、Special CO2 high pressure pump, with constant current and constant pressure mode, small size, low noise, suitable for laboratory users;

6、The extraction kettle volume can be selectively wide, 3L-30L optional, support customization;

7、The separation kettle has a window to observe the change of the amount of extract obtained in different time periods;

8、Carbon dioxide recycling, saving the cost of use, low carbon environmental protection。

With standard accessory:

ü Flexible high-pressure LCO2 line, 1.5 m, connecting cylinders to instruments;

ü External filter (filtration accuracy: 0.5um), supporting high pressure hose;

ü Special powder sample barrel;

ü 2 anti-static emptying pipelines, each 1.5 meters;

ü Spare extraction and separation kettle seal ring (10);

ü Installation tool set;

ü User manual and user guide;

ü One year warranty and free technical support for life。

Users need to equip:

Cylinders filled with carbon dioxide;

Entrainment agent (or other suitable medium)。